Brochure

Changsha Sapu New Materials Co.,Ltd.,relying on the innovation team of Changjiang Scholars from the Ministry of Education,has strong technical research and development capabilities,leading products with independent intellectual property rights,full-time high-performance diamond grinding wheels and cubic boron nitride wheels,and research,development,production and sales of powder metallurgy high-speed steel products,It is a professional high-tech enterprise that provides overall solutions and technical services for the grinding and polishing processing technology of cemented carbide,high-speed steel rotary bodies,cutting tools and other products.

Cermet bonded diamond/CBN grinding wheel

Through independent research and development,SAPP New Materials overcame the technical difficulties in the combination of bonding agent and diamond/CBN abrasive particles,and took the lead in developing single-phase homogeneous cermet bonding agent in China.The cermet bond has a mixed bond structure of metal bond and covalent bond.The proportion of the two bonds can be adjusted to control the holding force of the bond on the abrasive particles,so as to realize the advantages of abrasive particle passivation and self peeling,and the working surface of the product is self sharpening.The Sapp grinding wheel has the characteristics of high sharpness,high shape retention,easy repair,long service life,etc.

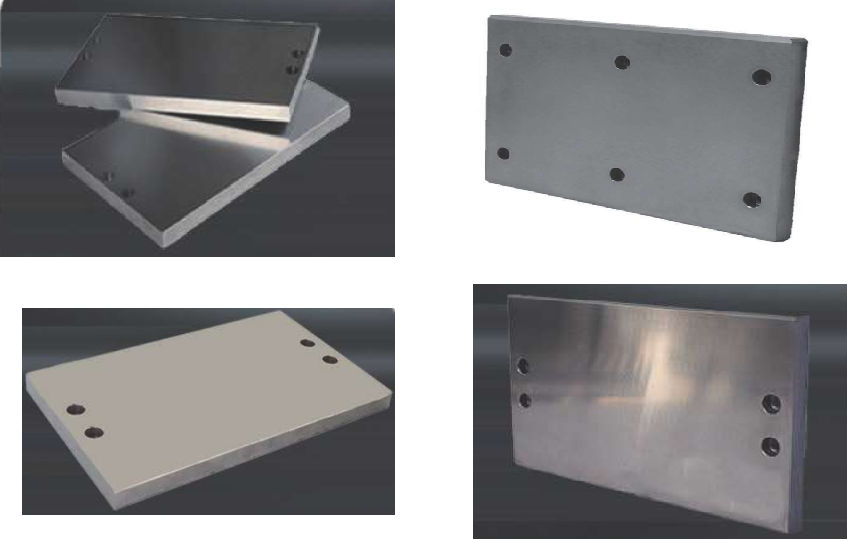

3D glass hot bending machine soaking plate

Sap New Materials is committed to producing high life and high quality TiNiCo superalloy soaking plates,which are suitable for hot bending equipment such as 3D glass and aspherical curved glass.The TiNiCo soaking plates maintain high plane accuracy for a long time in the process of high temperature hot bending,stabilize heat transfer and greatly improve the yield of hot bending glass.

Compared with traditional cemented carbide and ceramic soaking plates,TiNiCo superalloy soaking plates have the following characteristics:

1.Excellent high-temperature oxidation resistance(no powder loss at high temperature,keep the surface clean).

2.High high temperature strength(high temperature creep deformation resistance,high precision maintenance for a long time)and hardness(strong scratch resistance).

3.High thermal conductivity,large specific heat capacity,excellent thermostability.

4.Low friction coefficient,small friction with the mold,protect the mold.

5.Excellent chemical stability,non reactive with stainless steel and graphite.

6.No coating is required to avoid scratch and recoating of the coating,and the cost is low.

Powder metallurgy high speed steel

Powder metallurgy high speed steel eliminates the problem of composition segregation and coarse structure of traditional cast forged high speed steel.It has uniform,fine and isotropic structure,so it has high strength,toughness,wear resistance,and excellent machining and heat treatment properties.

SAP series of powder metallurgy high-speed steel products developed by SAP New Materials adopt a new powder metallurgy process.With high-quality powder as raw material,the products are alloyed and fully densified through near net shape pressing,activated sintering and reaction diffusion with controllable composition gradient.Only a small amount of machining is required to obtain tooling products that meet the requirements of various shapes and sizes.

Compared with traditional powder metallurgy high speed steel,SAP powder metallurgy high speed steel has the following characteristics:

1.It can prepare complex workpieces by near net forming,support shape customization,and reduce user processing costs;

2.Low impurity content(O≤60ppm,S≤80ppm,P≤50ppm);

3.It breaks through the alloying limitation of traditional smelting method and is convenient for composition adjustment;

4.He is good at preparing super hard phase strengthened powder metallurgy high speed steel;

5.Short production and delivery cycle.

SAP tool materials mainly include powder metallurgy high speed steel and steel bonded cemented carbide.The former includes die steel,high chromium stainless steel,cobalt free high speed steel,cobalt containing high speed steel,high niobium high speed steel and high vanadium high speed steel.

Language

Language